Depending on the different operating conditions, we have designed different solutions:

Capstream

It is a gravitational cap feeding system designed to guarantee the highest efficiency of the Sincro Bloc versions, according to the most advanced state-of-the-art.

The caps arrive already oriented to the top of the feeder and descent by simple gravity to cap chutes, without compressed air (clean feeding).

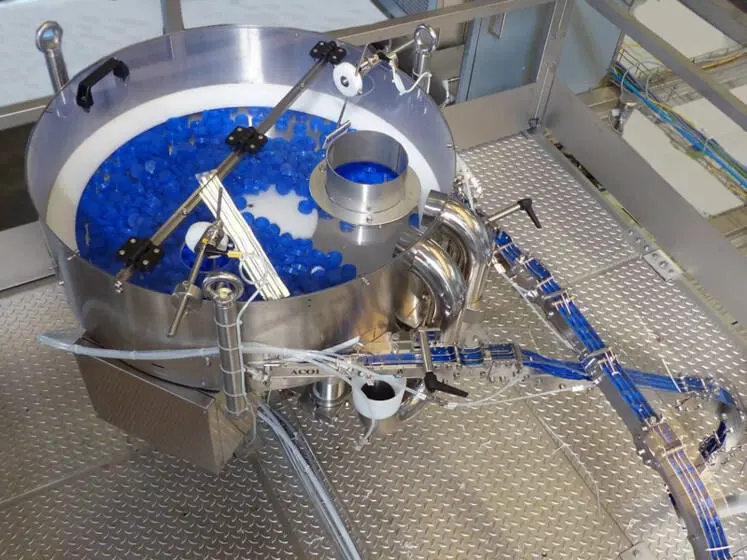

Twin/single Hopper

The Twin Hopper is composed of two cap hoppers and relevant descent channel to the pick and place. In the event of a blockage on the first, the system passes automatically to the second, allowing the operator to remove the blockage without stopping the capping operations until the machine is empty.

When using a single type of cap the single hopper with reverse-rotation solution is available.

Flat Buffer

This is a dynamic buffer, positioned between the hopper and the pick and place,

and is composed of an horizontal rotating disk where a sufficient number of oriented caps is hold to guarantee an accumulation that allows the operator to clear the blockage and completely empty the system.

Contact Us

Contact Us