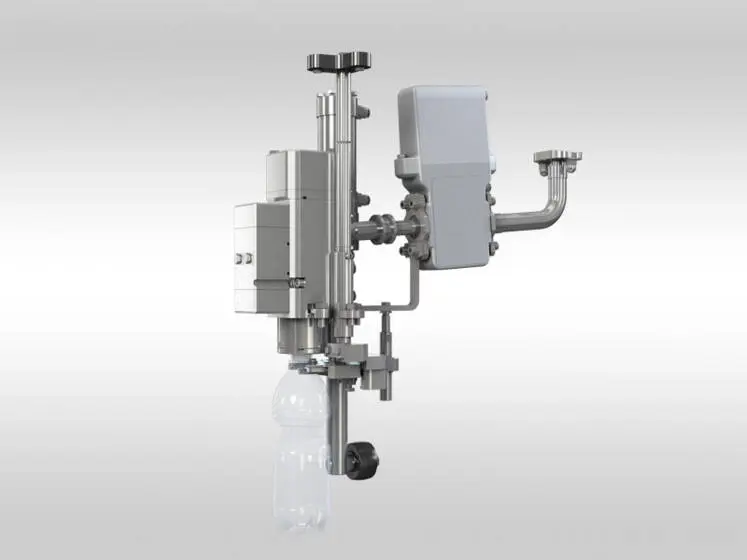

Is an electronic volumetric gravity filler for PET bottles, equipped with an extremely simple, clean and fast filling valve with no contact between valve and bottle, with a membrane valve to control the double filling speed. This solution guarantees high flow performance.

Ideal for water, milk, homogenized juices and clear products.

The machine can be configured with mass flow meters , for filling of low conductivity products ( such as edible oil or demineralised water).

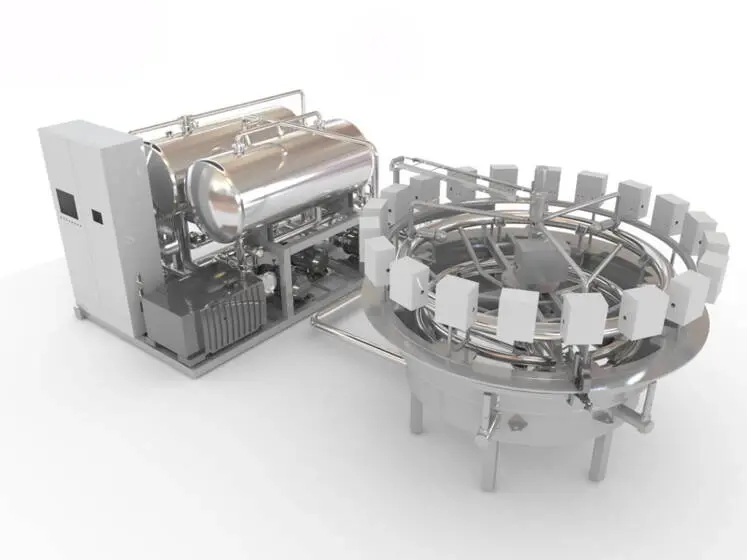

Output

Filler from 20 to 160 valves

from 8.000 to 72,000 b/hour based on 1,5 litres with water (ambient temp.).

Contact Us

Contact Us