- Home / Prototyping

- SIPA

Your Packaging Vision, Realized Quickly

SIPA offers efficient preform and bottle prototyping, enabling you to quickly evaluate your packaging concepts. Our dedicated team of experts, utilizing a 10,000 square meter facility housing 12 machines (including preform injection, single-stage, and blow molding systems), ensures prototypes that accurately represent your final product.

Comprehensive Prototyping Expertise

/

01

Preform Prototyping: We create preforms tailored to your design or find the optimal match from our extensive catalog. We testvarious PET resins, additives, and specialty resins to meet your specific needs.

Stretch-Blowing Expertise: We develop samples for a wide range of container sizes (50ml to 20+ liters) and applications across diverse industries (pharmaceutical, beverage, food, and more).

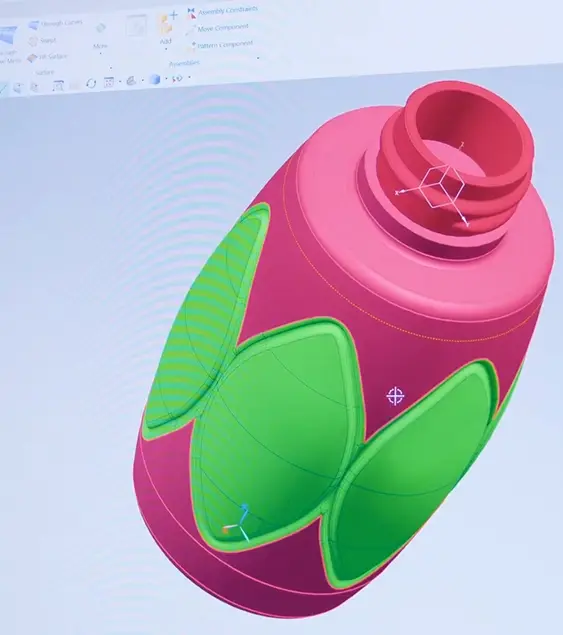

Rapid Prototyping with 3D Printing

/

02

For accelerated development, our 3D printing capabilities deliver tangible prototypes within hours. With just a digital design file (STL), we create transparent prototypes that can be customized like real bottles – colored, filled, capped, and labeled.

Testing and Collaboration

/

03

We conduct thorough testing, providing samples for on-site line trials to ensure your packaging meets technical standards and aligns with your goals for cost, flexibility, safety, and sustainability. We frequently collaborate with our customers' R&D centers, fostering efficiency throughout development.

Global Reach

/

04

With prototyping centers in Italy, China and the United States, SIPA remains committed to providing localized support and rapid response times, helping you achieve a faster time-to-market.

1 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

2 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

3 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

4 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

5 An optional caption for the image that will be added to the gallery. Enter any descriptive text for this image that you would like visitors to be able to read.

-

Discover more/02

- SIPA

Discover the other sections of Packaging Solutions

Explore our comprehensive range of packaging services: from initial design and engineering to prototyping containers that bring your unique packaging vision to life.

Innovation

07

/

08

/

2025

Innovation

Our state-of-the-art laboratory facilities offer a complete suite of tests for preforms, containers (including jars, handled containers, and beer kegs), caps, closures, handles, and the diverse materials they comprise.

Validation

27

/

06

/

2025

Validation

Our state-of-the-art laboratory facilities offer a complete suite of tests for preforms, containers (including jars, handled containers, and beer kegs), caps, closures, handles, and the diverse materials they comprise.

Prototyping

27

/

06

/

2025

Prototyping

SIPA offers efficient preform and bottle prototyping, enabling you to quickly evaluate your packaging concepts. Our dedicated team of experts, utilizing a 10,000 square meter facility housing 12 machines (including preform injection, single-stage, and blow molding systems), ensures prototypes that accurately represent your final product.

Packaging engineering

27

/

06

/

2025

Packaging engineering

At SIPA, we craft packaging solutions that not only catch the eye on the shelf but also perform great. Our team works closely with you to understand your specific technical needs and goals, then tailors solutions to optimize performance while considering factors like weight reduction, the use of recycled materials, or alternative materials to PET.

Design

26

/

06

/

2025

Design

SIPA doesn't just design bottles; we engineer complete packaging ecosystems that elevate your brand and make it stand out on the shelf. With four decades of expertise in PET container machinery manufacturing, we possess an unmatched expertise in combining container design with performance.

News for this products

Intelligence in the mold: SIPA unveils XBRAIN for advanced digital management

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements

13

/

01

/

2026

Celebrating our sustainability achievements

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

12

/

12

/

2025

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW Wins Top Sustainability Award

13

/

11

/

2025

SIPA's XFORM RENEW Wins Top Sustainability Award

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

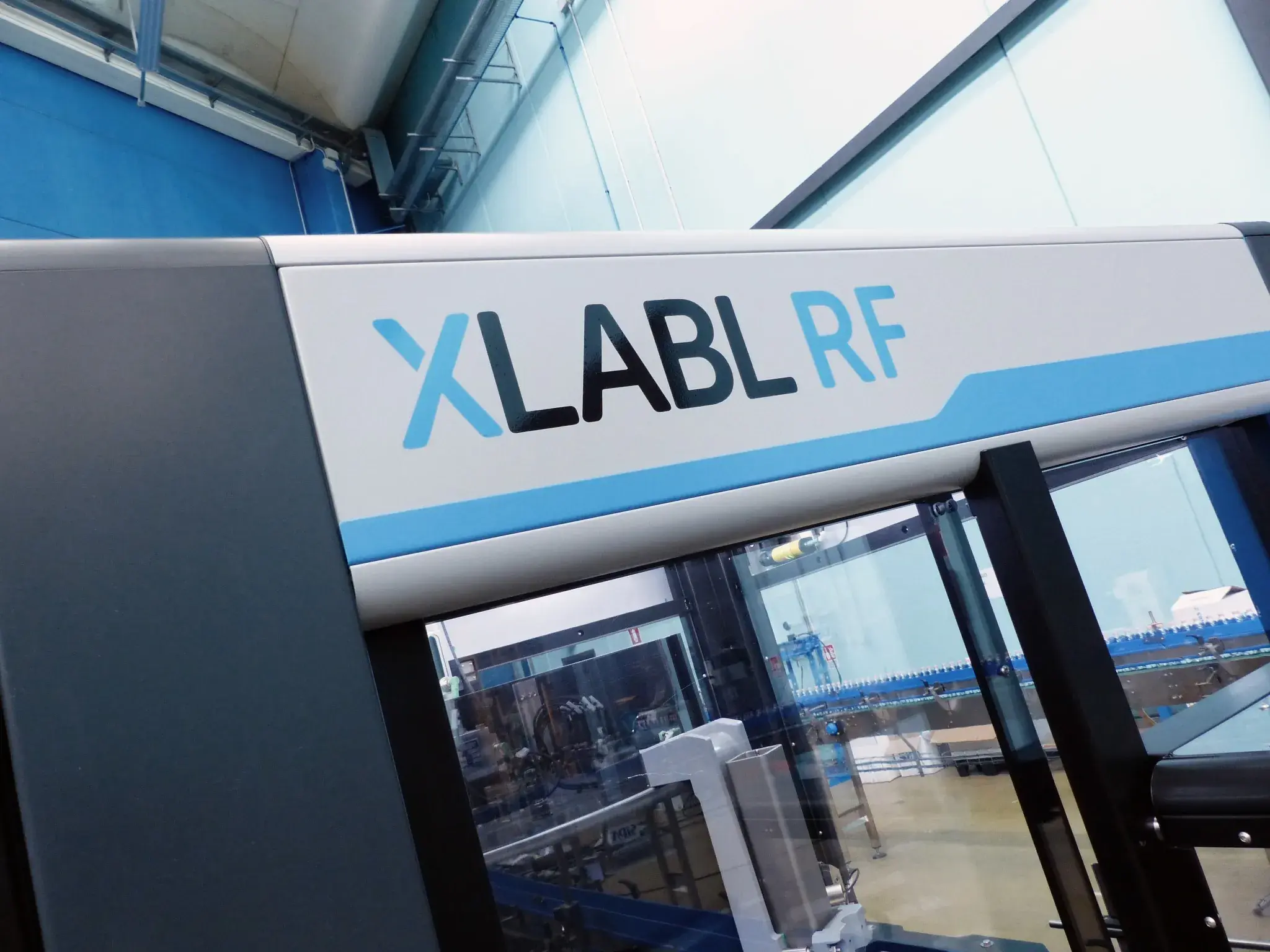

Introducing XLABL RF: New Frontier in Roll-Fed Labelling Technology

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

27

/

01

/

2026

Intelligence in the mold: SIPA unveils XBRAIN for advanced digital management

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

13

/

01

/

2026

Celebrating our sustainability achievements

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

12

/

12

/

2025

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

13

/

11

/

2025

SIPA's XFORM RENEW Wins Top Sustainability Award

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

07

/

11

/

2025

Introducing XLABL RF: New Frontier in Roll-Fed Labelling Technology

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

Case Histories for this products

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

17

/

02

/

2026

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

14

/

01

/

2026

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

10

/

12

/

2025

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

01

/

10

/

2025

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.