| MODEL | CAPACITY |

| Carbo-SD 12 | Up to 12,000 l/h |

| Carbo-SD 27 | Up to 27,000 l/h |

| Carbo-SD 34 | Up to 34,000 l/h |

| Carbo-SD 42 | Up to 42,000 l/h |

| Carbo-SD 54 | Up to 54,000 l/h |

| Carbo-SD 66 | Up to 66,000 l/h |

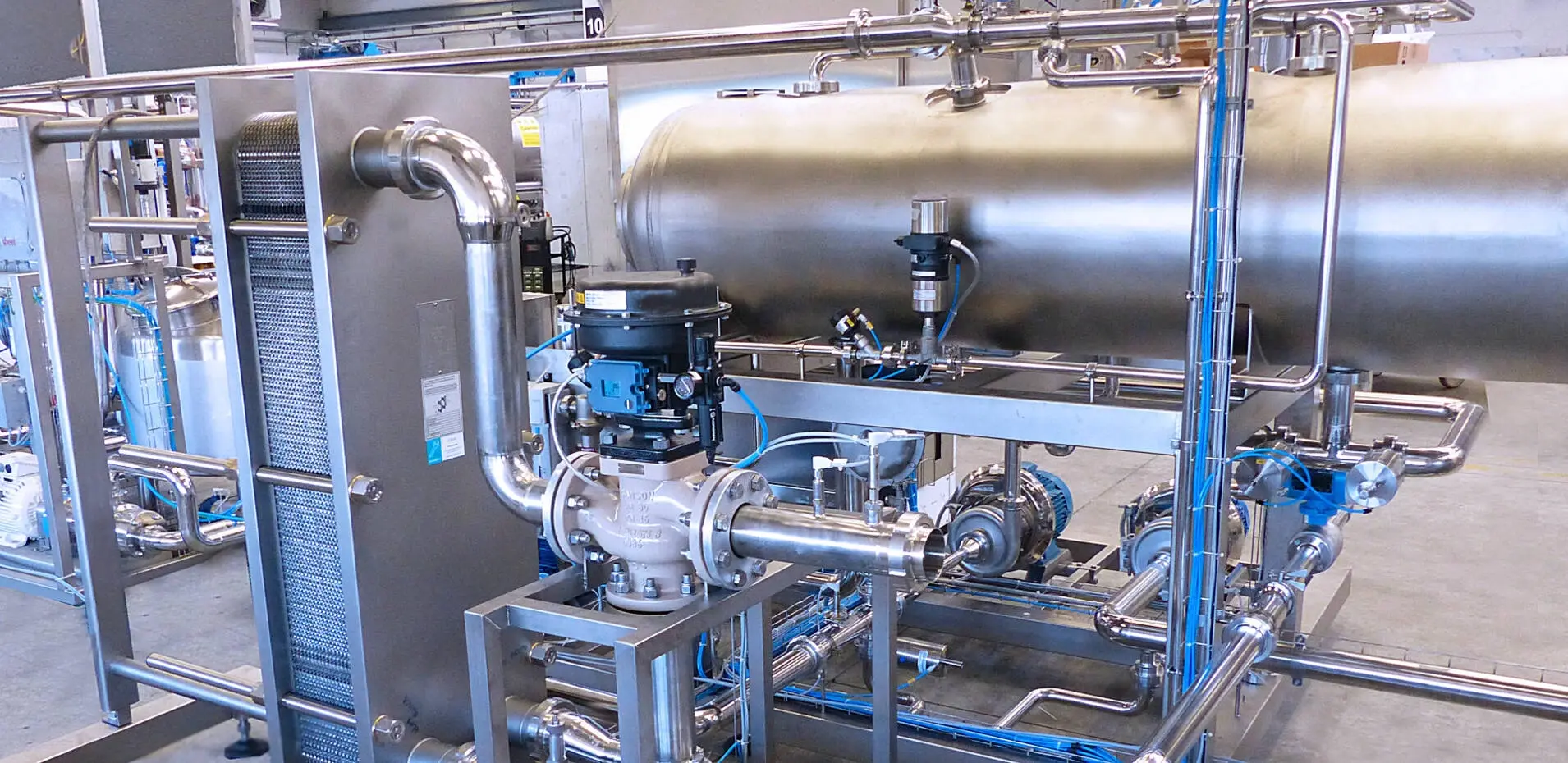

Carbonation

The CO2 is fed to the system by using a modulating valve and a mass flow meter, a special diffuser is installed to obtain an homogeneous dissolution of the desired CO2 quantity, moreover the dispersion of gas is realized through a static mixer to achieve a fine mixing of CO2 into the final product.

| MODEL | CAPACITY |

| Carbo-SD 12 | Up to 12,000 l/h |

| Carbo-SD 27 | Up to 27,000 l/h |

| Carbo-SD 34 | Up to 34,000 l/h |

| Carbo-SD 42 | Up to 42,000 l/h |

| Carbo-SD 54 | Up to 54,000 l/h |

| Carbo-SD 66 | Up to 66,000 l/h |

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

Please let us know how we can assist you. We have dedicated contact forms for specific inquiries, ensuring your request reaches the right department for a swift and accurate response.

Drinktec | 2025