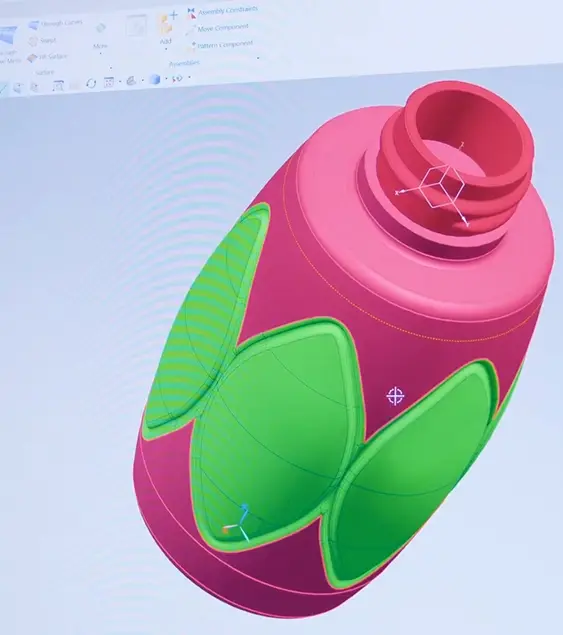

Crafting packaging that stand out and perform

At SIPA, we blend creative design with deep technical expertise to engineer packaging that stands out and performs perfectly. With decades of experience, we transform your vision into innovative containers. Explore this section for examples of our work and see how we can bring your next packaging project to life.

1

Contact Us

Contact Us