MATERIAL:

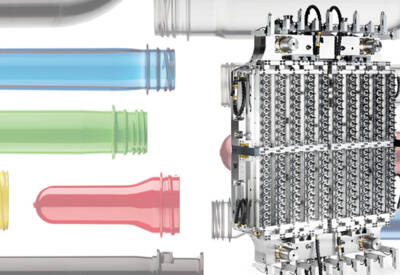

100% PET, 100% OPP

SHAPE:

round, square, oval, jars, heat resistant jars

SIZES:

from 200 to 1600 ml

NECK DIAMETER:

from 50 to 110 mm

HEAT SET & PASTEURISABLE CONTAINERS:

many of these products are hot filled or pasteurised to eliminate the bacterial load. SIPA has developed solutions with special necks and bottles with particular shapes for this type of filling, that reduce weight or eliminate the need to use expensive labels. Recently, SIPA developed a new technology for the production of containers capable of standing up to extremely high filling and pasteurisation temperatures, > 92°C, allowing an extension of the range of products that can be bottled in PET rather than glass, and offering unbreakability and a reduction in packaging weight

WIDE MOUTH JARS:

Here again, conversion from glass covers the majority of the applications for this type of container. The use of jars is mainly dedicated to various food applications in which the human hand or a spoon must be permitted to enter the container to pick up the content. In particular it is important that when you spoon the content, the neck finish is easy to clean internally, in order to avoid leaving residue on it. Conversion from glass jars covers most of the applications for these containers. The main characteristics required for these jars are vacuum resistance and reduced neck finish ovality

BARRIER CONTAINERS:

In order to prolong product shelf life, containers can be produced with different types of barrier. To enhance light, humidity, CO2 and oxygen barrier properties of every type of plastic container, several solutions are available: the bottles can be produced with the addition of barrier agents blended with the resin (nylon MXD6, EVOH, oxygen scavengers) or from multilayer preforms (PET+EVOH, PET + Nylon or PET+Nylon+barrier additive)

POLYPROPYLENE CONTAINERS:

PP is an interesting resin thanks to its peculiar features: water barrier, high temperature resistance and chemical inertia. For this reason, PP can access markets where PET is not indicated. Thanks to its high temperature resistance, PP is also highly suitable when a high hot filling temperature is required or steam sterilisation (at 121°C) is needed, e.g. medical and pharmaceutical and baby food industries. It is also suitable for applications requiring high humidity barrier performance, e.g. powder and soluble food