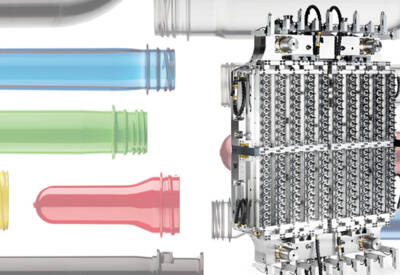

MATERIAL:

PET, recycled PET, reground PET, OPP

SHAPE:

round, square, oval, symmetrical & asymmetrical, proprietary

SIZES:

from 100 ml to 20 litres

NECK DIAMETER:

from 14 mm to 165 mm

OVAL CONTAINERS:

Oval container means a container with different base length and width. It can be centred neck or off-centred neck. The technological challenge in the production of oval containers is to achieve a uniform material distribution all around the bottle.

The technology required to compensate the different radial stretching ratio on the short and long sides of the bottle makes use of a preferential heating oven equipped with infra-red lamps dedicated to reheat the preforms asymmetrically: in the oven the preforms do not rotate, so the re-heating process is concentrated on two opposite sides.

Some containers also require the thread to be oriented, as special closures are to be applied. This is the case for many bottles for detergents, equipped with trigger sprayers that are to be oriented in the direction of the short side. In order to give the thread the proper position compared to the bottle, the machine producing the container is equipped with a special system to orient the preforms in the correct position before entering the preferential heating oven.

LARGE SIZES:

PET is becoming the most flexible and cost effective solution for the manufacturing of large size containers, from 5 to 30 litres, for chemical products. Wide mouth jars: wide mouth containers are frequently required for the cosmetics sector

JARS:

wide mouth containers are frequently required for the cosmetics sector