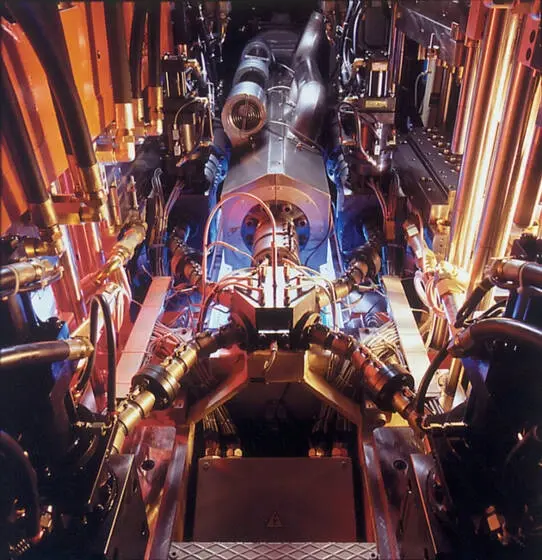

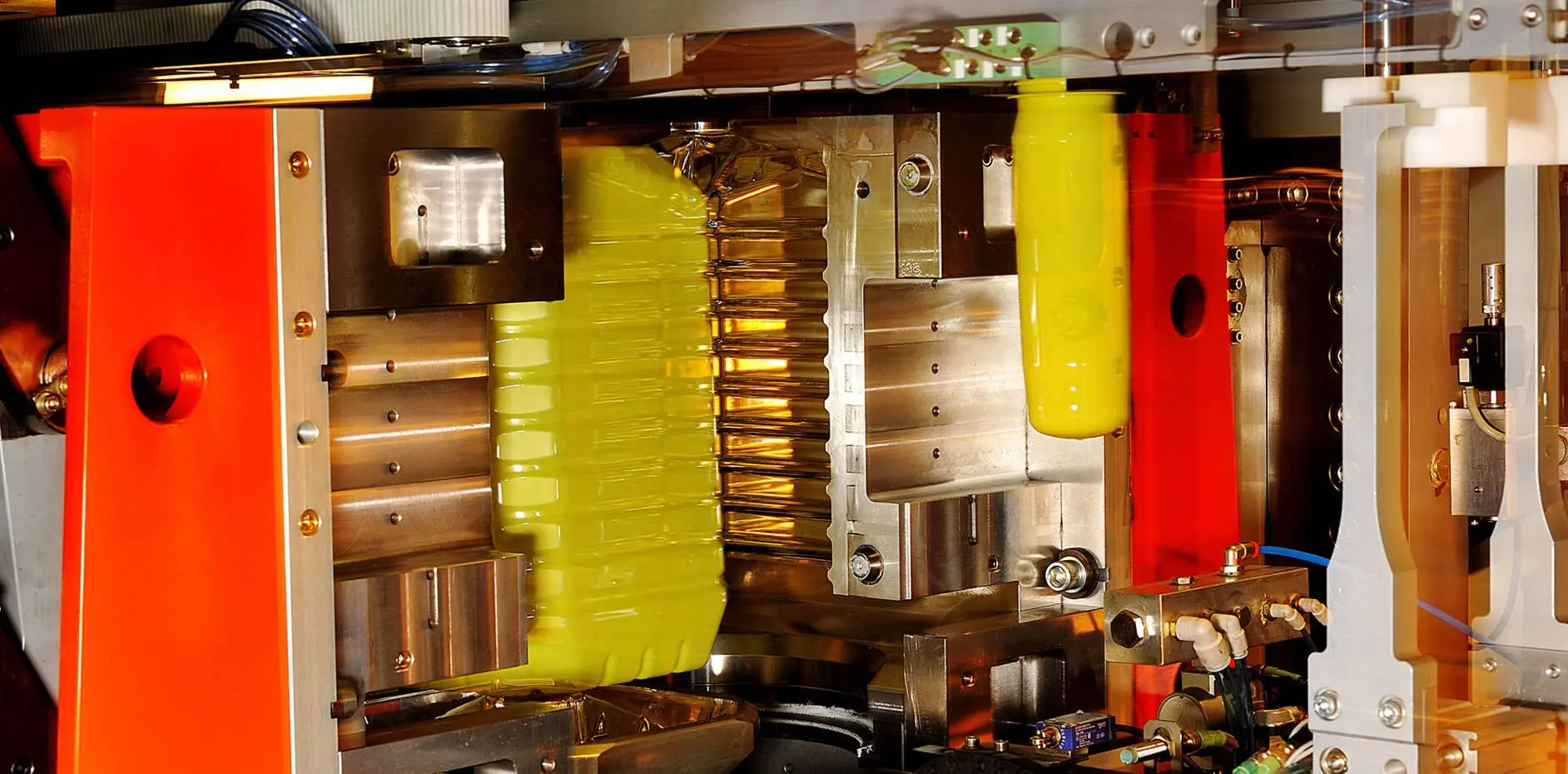

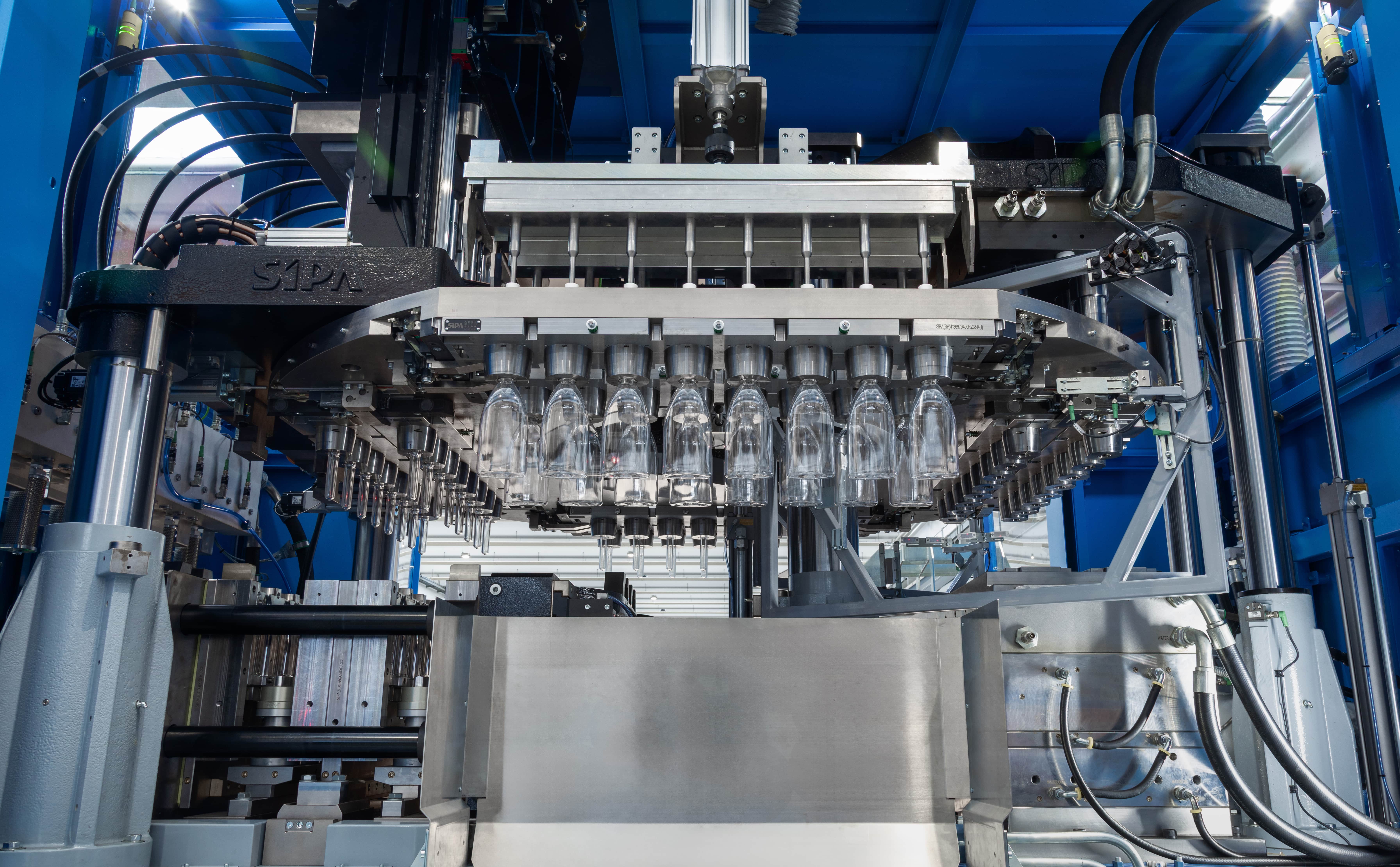

SIPA integrated systems, the ECS range, start from the raw material, the resin, and takes the process through to the finished container without any interruption, with total automated control of all phases of production. Costs associated with traditional two-step processes (such as preform handling, preform storage, preform cooling & reheating) are simply not part of the integrated process.

These systems are extremely versatile and can produce a wide range of standard and customized containers: lightweight bottles for standard or hot fill use, ultra-clean or aseptic bottles, pasteurizable containers, warm filled bottles, wide mouth jars, round or square-shaped bottles with capacities up to 3 liters, oval, asymmetric or tailor-made containers, and advanced bottle production systems. A comprehensive, competitive range that makes ECS machines a sure answer to a wide variety of requirements.

Contact Us

Contact Us