Bottle production systems

SIPA has always maintained the objective of serving its customers in the broadest and most responsive way and, by offering the full range of solutions for container production, we are able to support customers with expert advice on the most suitable system to satisfy their specific needs.

-

Home/ Bottle production systems

- SIPA

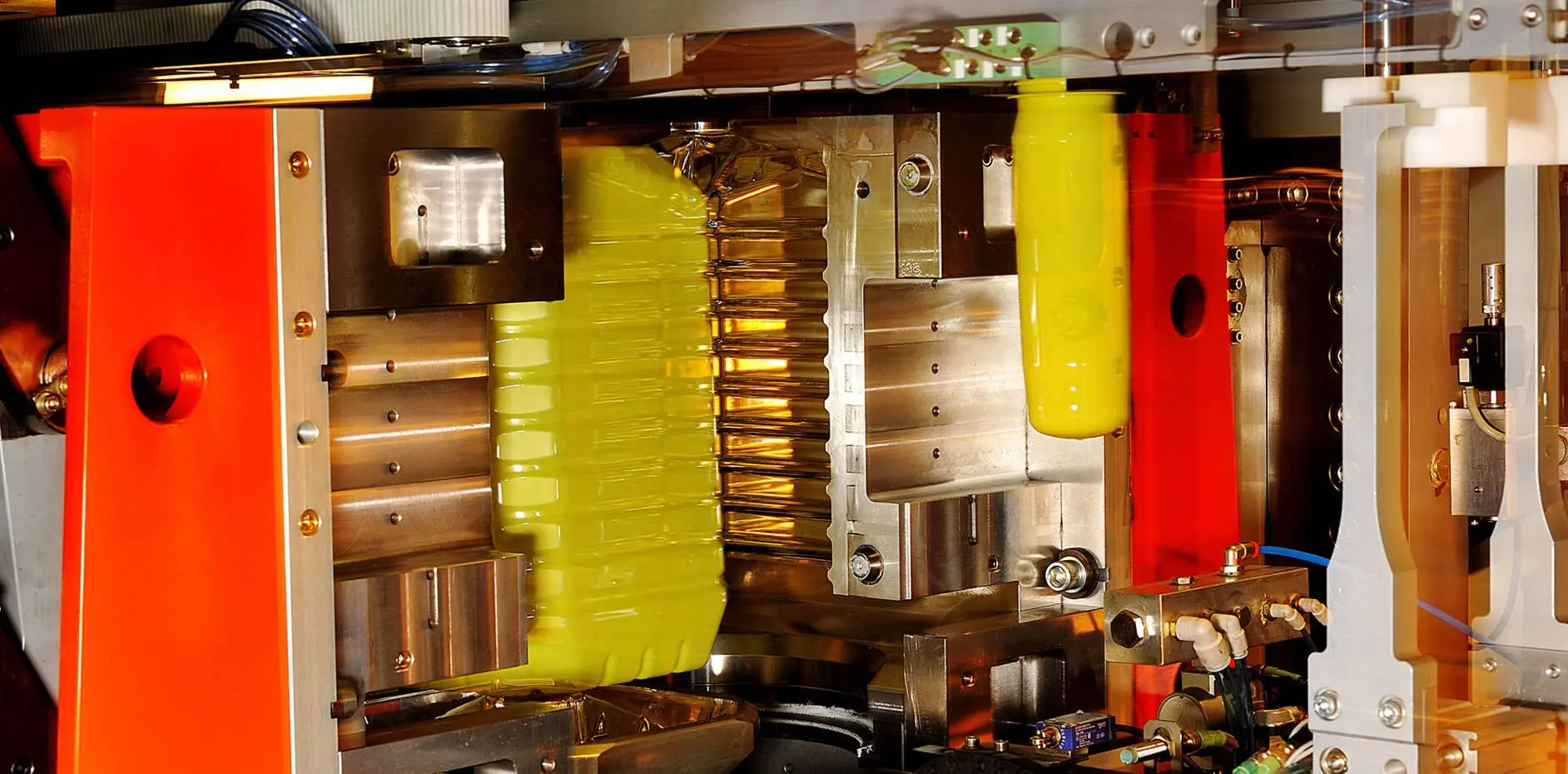

Single-stage and two-stage PET bottles manufacturing systems: versatility and performance

The production of preforms and bottles can be made with a 1-step or a 2-step process:

- The 1-step process, based on the concept of integrating the preform injection process with the preform stretch-blowing process, results in a container obtained directly from plastic resin in a single machine.

- The 2-step process features the manufacture of plastic containers in two separate stages: first preforms are injection molded on an injection machine and then are re-heated and stretch-blown on a blowing machine.

- The 1-step process, based on the concept of integrating the preform injection process with the preform stretch-blowing process, results in a container obtained directly from plastic resin in a single machine.

- The 2-step process features the manufacture of plastic containers in two separate stages: first preforms are injection molded on an injection machine and then are re-heated and stretch-blown on a blowing machine.

SIPA has held a unique position in the market

SIPA has held a unique position in the market as the sole manufacturer supplying both 1-step and 2-step solutions as well as injection and blowing molds for SIPA and non SIPA machines.

Our solutions for the production of PET containers include high-speed rotary blow molding system, the XTRA range, linear blow molding system, the highly flexible SFL range of machines, the SFL for large size containers as well as high-speed 1-step systems, the ECS FX and medium low-speed 1-step systems, the ECS SP range.

To complete our range of solutions, we design and produce in-house blowing molds to fit our systems as well as most of the major brands of stretch blow molder machines and we offer a complete service of container design and prototyping.

-

Discover more/02

- SIPA

Discover the other sections of Bottle production systems

SIPA offers a wide and versatile range of solutions for PET bottle production, catering to diverse industry needs

ECS SP ISBM systems

11

/

02

/

2026

ECS SP ISBM systems

Explore the ECS SP ISBM systems by SIPA, offering flexibility and top quality for your bottle manufacturing needs. Discover the benefits

ECS FX ISBM systems

05

/

07

/

2025

ECS FX ISBM systems

Discover the ECS FX ISBM systems, designed for high-efficiency bottle production and tailored to meet specific industry needs. Learn more about these systems

SFL for LARGE SIZE containers

03

/

07

/

2025

SFL for LARGE SIZE containers

Find out about our SFL systems for large-size containers, ideal for industries needing robust packaging solutions. See how we can meet your needs

SFL linear blowing systems

02

/

07

/

2025

SFL linear blowing systems

Learn about our SFL linear blowing systems, the cutting-edge solution for high-versatility production with exceptional quality. Explore the features

XTRA rotary blowing system

01

/

07

/

2025

XTRA rotary blowing system

Explore the XTRA Rotary Blowing System, a pinnacle of innovation in high-speed bottle manufacturing. Learn how it can revolutionize your production

Work with us

We are always looking for dynamic and proactive people, oriented towards growth and achieving results. On this page you can find the list of our open positions. Click on an offer to learn more about the position and, if you match the required profile, fill out the form. If there are currently no positions of interest or in line with your profile, send us your CV using the Spontaneous Applications section.

Contact Us

Please let us know how we can assist you. We have dedicated contact forms for specific inquiries, ensuring your request reaches the right department for a swift and accurate response.

By your side, beyond the limits.

Every shape, every technology, every need about PET packaging.

By your side, beyond the limits.

Every shape, every technology, every need about PET packaging.

Drinktec | 2025