At SIPA, we craft packaging solutions that not only catch the eye on the shelf but also perform great. Our team works closely with you to understand your specific technical needs and goals, then tailors solutions to optimize performance while considering factors like weight reduction, the use of recycled materials, or alternative materials to PET.

Optimal Design, Maximum Performance

We prioritize geometry optimization in our preform and container engineering, balancing material properties, weight, and application requirements. This results in lightweight yet durable packaging that reduces costs, enhances sustainability, and streamlines logistics.

Our engineering knowledge extends beyond weight reduction, as we meticulously optimize each container for seamless integration with your entire production line, from filling to palletizing.

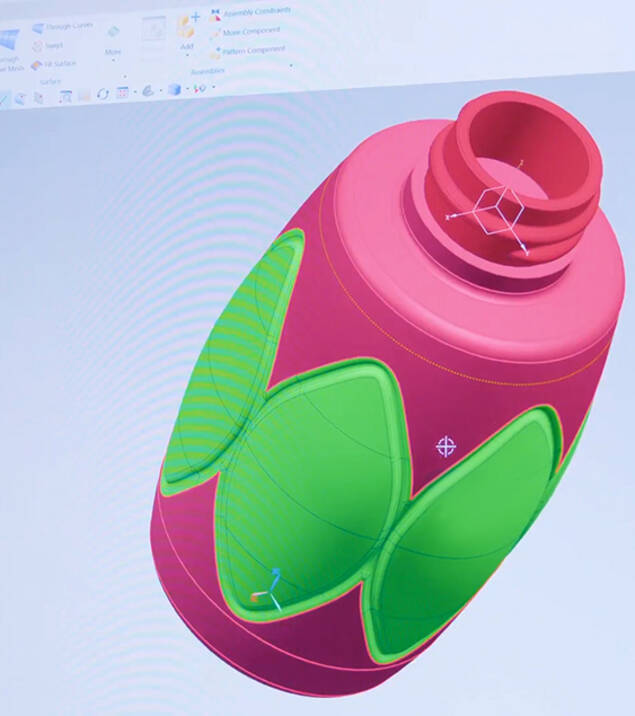

Virtual Prototyping for Real-World Results

Leveraging cutting-edge digital twin technology and finite element analysis (FEA), we create virtual models that accurately predict real-world container performance under various conditions. This allows us to optimize designs and identify potential issues before physical prototyping, saving you time and resources.

Optimization at Every Level

Our methodology empowers you to confidently launch new package shapes or reduce costs without sacrificing performance. We meticulously optimize every aspect of your packaging, from material selection to production processes, ensuring a perfect balance of performance and cost-efficiency.