Type

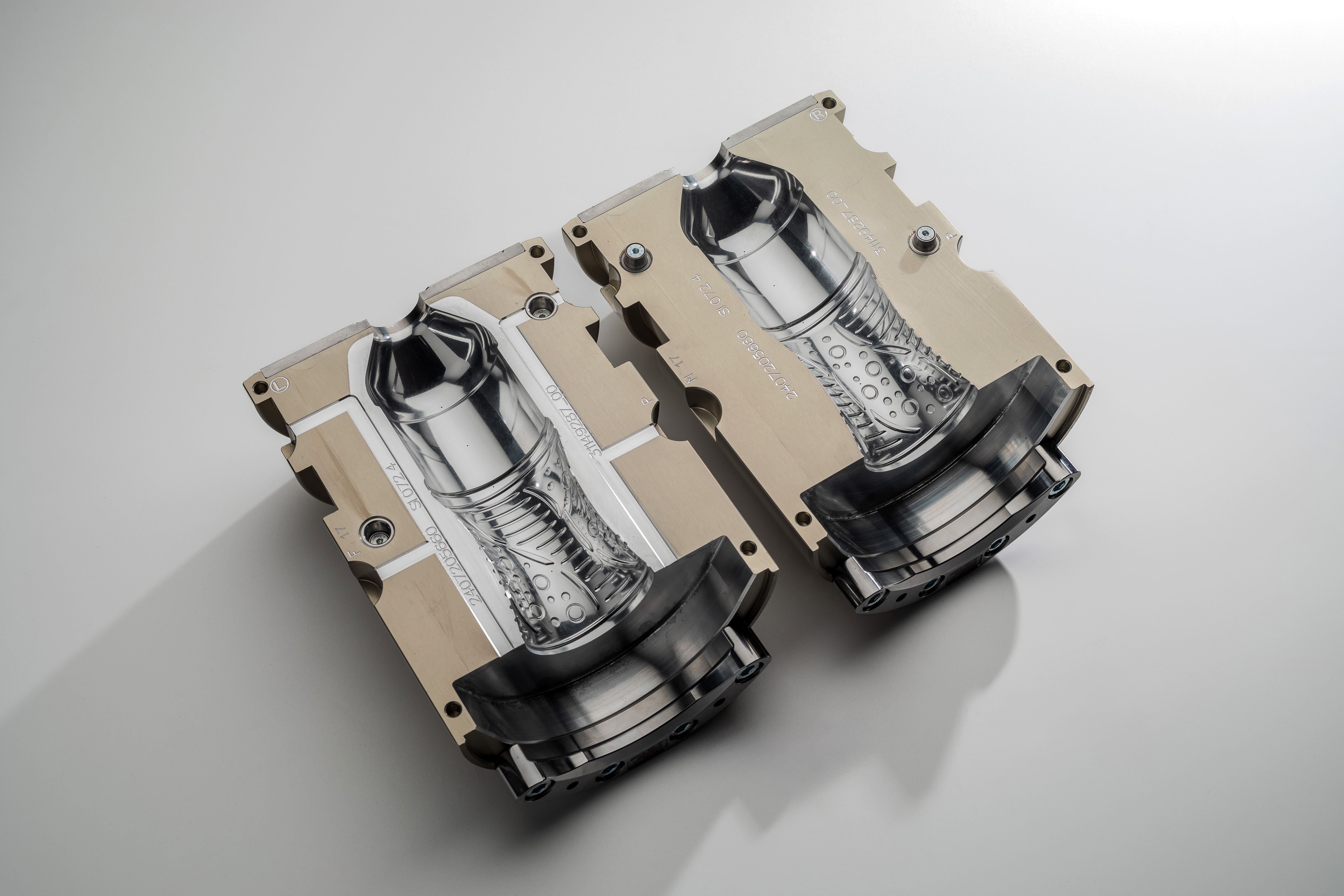

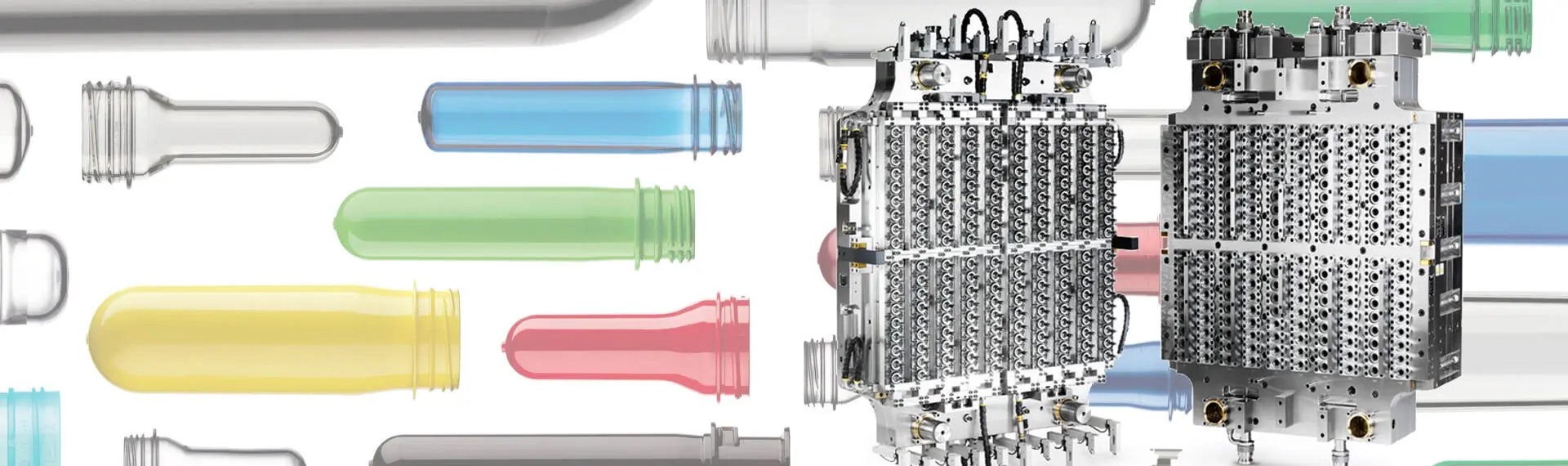

Our Portfolio Includes- Molds for linear blow molders

- Mono-block molds for rotary blow molders

- Quick-change molds (shell molds) for rotary blow molders

- Quick-change conversion system with mother mold and quick-change shell molds

- Interchangeability kits to make quick-change molds compatible with different types of blow molders

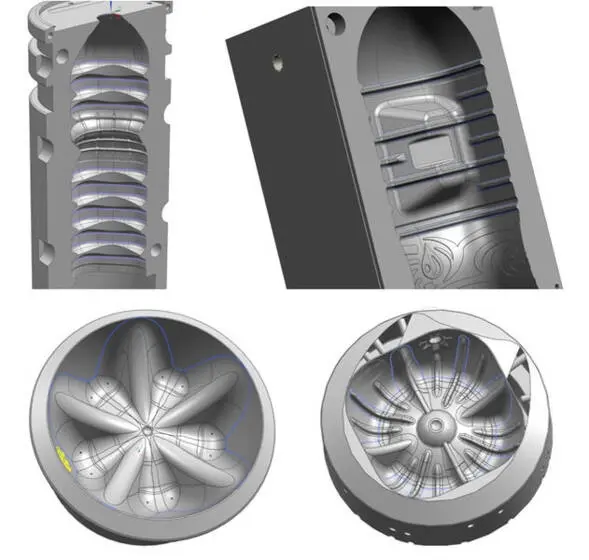

| COMPONENT | MATERIAL | TREATMENTS (IF ANY) |

| CAVITY | ALUMINUM ALLOY 7xxx | ANODYZING if required |

| CAVITY (aluminum-heat set) | ALUMINUM ALLOY 5xxx or equivalent | ANODYZING if required |

| CAVITY (stainless steel) | CRS 420 series | HARDENED AND TEMPERED |

| BASE | ALUMINUM ALLOY 7xxx | ANODYZING if required |

| BASE (stainless steel) | CRS 420 series | HARDENED AND TEMPERED |

Contact Us

Contact Us