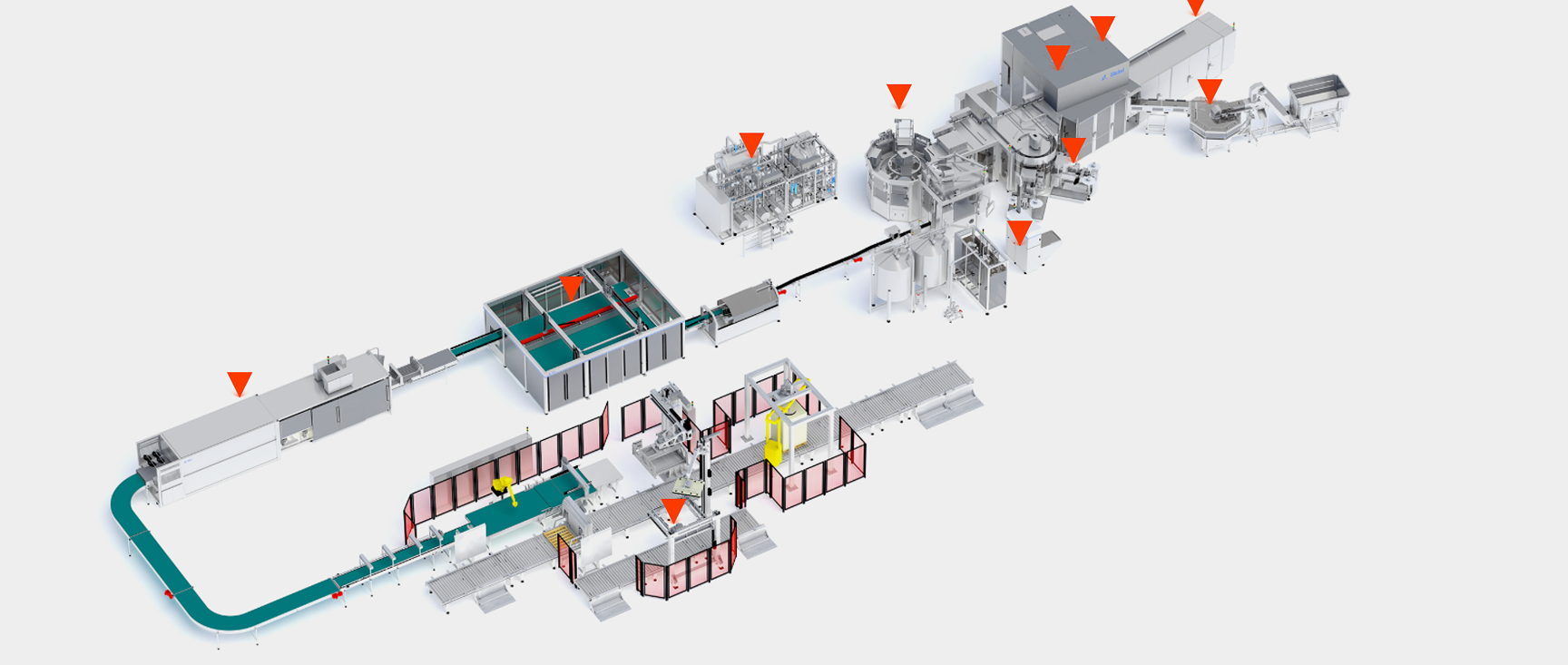

Packaging requirements

The ability to innovative packaging design, to optimise weight and to manufacture preforms and containers even for large sizes are key for this application.

- Italian design that combines bottle aesthetics and mechanical performance

- Lightweight packaging. Finding the best compromise between lightest possible weight and mechanical resistance, to support filling line handling, storage and transportation and to guarantee the shelf-life

- New neck and new base design, to reduce weight where it is not needed and to improve container stability

- Ergonomic shape to improve the consumer’s grip also in case of lightweight bottles

- Wide range of solutions for large size containers (from 5 to 20 litres): stackable, self-collapsible, returnable or one-way 5 gallon containers for dispensers, innovative handle solutions.

01

Attractive packaging and unique shape design

02

Lightweight (find best weight-mechanical resistance ratio)

03

Ergonomic shapes to improve the consumer's grip

04

Large convenience sizes, and dispenser container

MATERIAL:

- PET, recycled and reground PET, bio-based resins

SHAPE:

- round, square or proprietary shapes

MATERIAL:

- from 150 ml to 20 litres

NECK DIAMETER:

- from 24 mm to 55 mm

- Our Machinery / 01

- SIPA

Contact Us

Contact Us

.webp)

-min.jpg)

-min.jpg)