Sipa and the environment

-

Home/ Sustainability

- SIPA

Sustainability. Technologies and actions for recycling with a view to a circular economy.

SIPA's commitment to the environment is continuous, effective, measurable.

SIPA has always focused on a more reasoned consumption of PET, enabling its customers to produce lighter-weight containers, removing material where it is not necessary. All this without compromising any of the container's mechanical properties or aesthetic features.

SIPA has always focused on a more reasoned consumption of PET, enabling its customers to produce lighter-weight containers, removing material where it is not necessary. All this without compromising any of the container's mechanical properties or aesthetic features.

SIPA specialists are experts in the sustainability loop, they plan to reduce resin consumption, energy and CO2 emissions in defense of the environment. In addition, they are among the pioneers of the "circular" approach: they design and rethink new technologies in order to give new life to post-consumer resources putting them back into the system. A forward-looking vision that combines environmental sustainability and economic development to deliver a better world to future generations.

Environmental policy

SIPA considers environmental protection and sustainable development to be fundamental and strategic factors in conducting and developing its business.

This commitment is clearly revealed not only in designing products and solutions ready for the circular economy, but also in ongoing improvement of the Environmental Management System in compliance with the ISO 14001 standard to improve the company's environmental performance.

A sustainable environmental development by achieving a balance between corporate economic growth on the one hand and environmental protection on the other, taking the needs of the environment into account in all the company's actions.

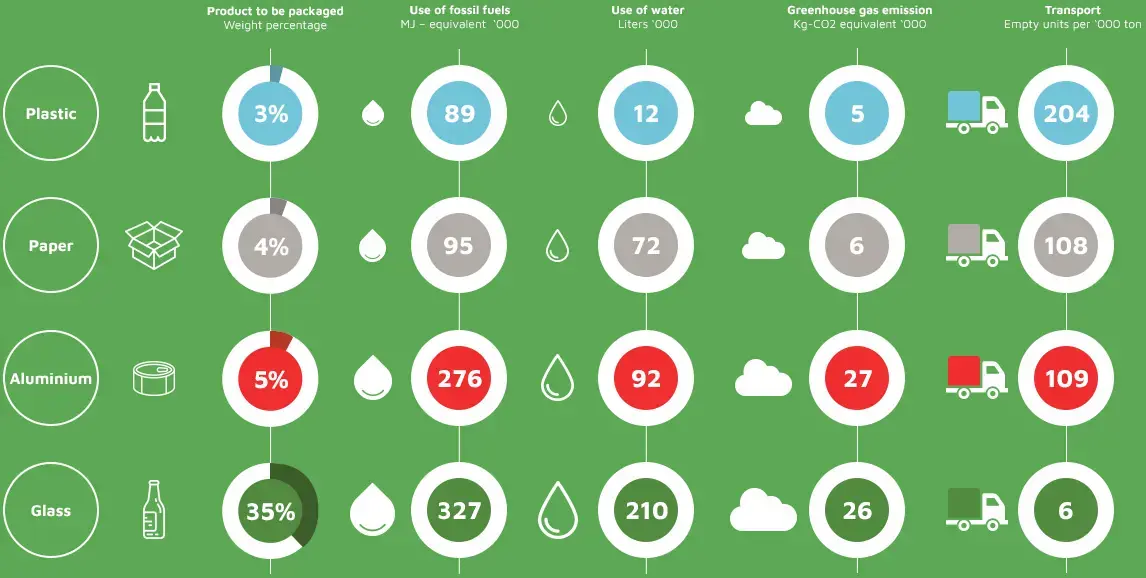

Environmental footprint of plastic

-

Reduction of raw material

A more rational consumption of PET is the way to a greater environmental sustainability. For some time now, SIPA has been designing machines capable of producing lighter containers, shaving material where it is not needed. All this without compromising any mechanical or aesthetic property of the container, and without disadvantages for the customer

-

Reduction of consumption

SIPA was one of the first players to successfully process plastic bottles from plants and renewable sources. The company carries out a sustainable innovation program through continuous technical upgrades to minimize the environmental impact of the machines, increasing their efficiency and at the same time reducing energy, compressed air and water consumption.

Work with us

We are always looking for dynamic and proactive people, oriented towards growth and achieving results. On this page you can find the list of our open positions. Click on an offer to learn more about the position and, if you match the required profile, fill out the form. If there are currently no positions of interest or in line with your profile, send us your CV using the Spontaneous Applications section.

Contact Us

Please let us know how we can assist you. We have dedicated contact forms for specific inquiries, ensuring your request reaches the right department for a swift and accurate response.

By your side, beyond the limits.

Every shape, every technology, every need about PET packaging.

By your side, beyond the limits.

Every shape, every technology, every need about PET packaging.

Drinktec | 2025

Contact Us

Contact Us

-1.png)