- Home / Preform tooling

- SIPA

Injection tooling for the manufacturing of PET preforms: solutions for life

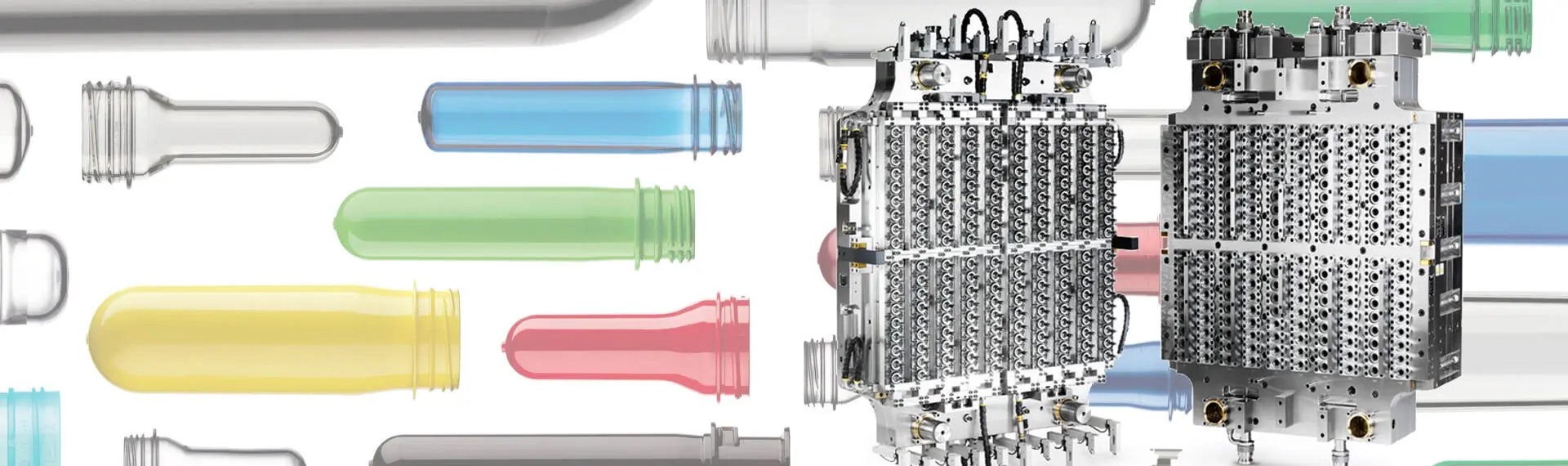

In second place in the world for the production of molds, SIPA is able to deliver global tooling programs for new molds or mold conversions from single to 200 cavities. To ensure top quality, every SIPA mold is tested before shipping on dedicated XFORM machines.

HIGHLIGHTS

/

01

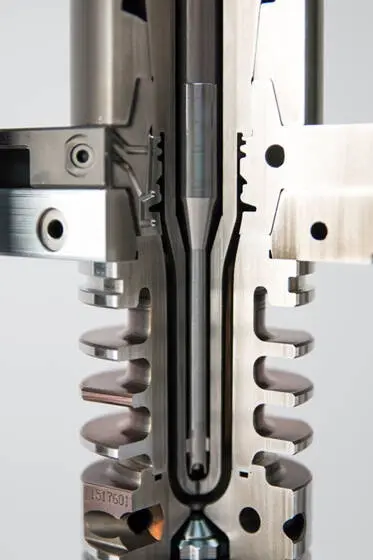

- Innovative design of injection components: less wear, lower risk of flashing, better cooling, excellent quality ofparting line

- Easier filling ability of injection mould thanks to our XMOULD technology which reduces the friction and improves cycle time

- Optimized cooling layout to support fast cycle times and save energy costs

- Patented hot runner technology to minimize hot runner downtime

- 11millions lif cycle guaranteed without need of components refurbishing with LongLife solution

- special hot runners design to reduce material stress and working pressures

XMOULD

/

02

XMOULD is an innovation from Sipa which allows reduction of friction between molten PET and molding surface of the injection stacks during injection phase, allowing production of thin-wall performs with length on wall thickness ratio above 50 (L/t in the range of 50 to 55 possible), so better/optimized thickness distribution on final packaging (avoid the accumulation of material on zone as under-neck and bottom areas).

XMOULD technology givesdesigners the power to create lightweighted preforms which do not compromise performance of the final container.Besides the possibility to reduce preform thicknesses, this solution also improves cycle times due to friction reduction at filling phase.

Available on new or legacy tooling, only special injection stacks are required to enjoy the XMOULD technology, no changes required neither on the machine nor the hot runner.

LONGLIFE

/

03

Range of solutions on shaping components to extend the life of the cold half of our preform molds (optional).

11million life cycles guaranteed (flash < 0.2mm) without need of components refurbishing, following lifetime conditions. Significantly reduced refurbishment costs.

HOT RUNNERS

/

04

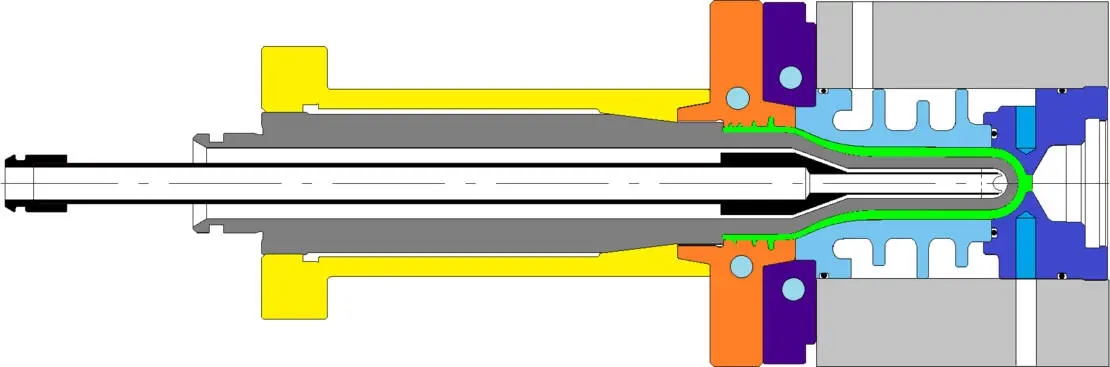

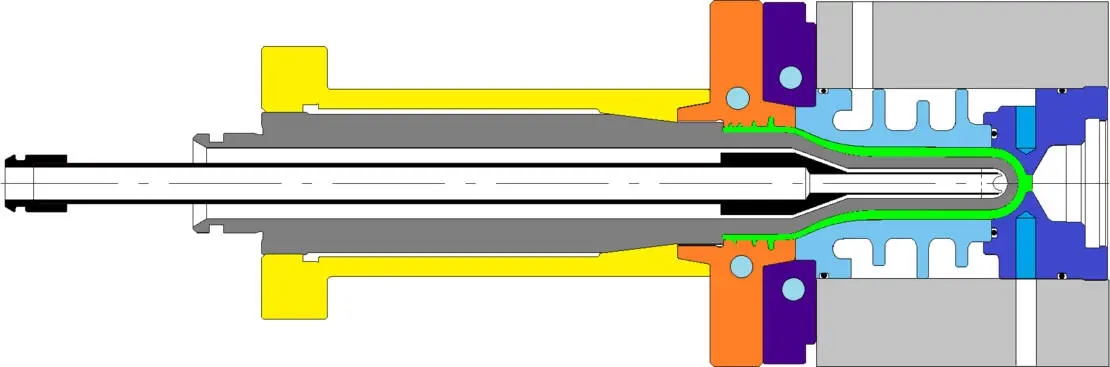

Hot runner with Xflow technology:

- Best in class balancing

- Low pressure drop

- Increased injection speed, shorter cycle time

- Optimal preform weight distribution

- Low PET degradation and no dead spots

- Easy maintenance

- Compatible with industry standard cold halves and machinery

COLD HALVES

/

05

- Smart lock design applied regardless of the position of the parting line: better precision and higher durability with double tapers always implemented

- Flange design to allow a significantly better cooling in the very critical split-line area

- Self-centering gate insert, allows for a reduction of the parting line in the base area of the preform

OUR PORTFOLIO IS CONSTANTLY EXPANDING

/

06

- Complete molds (Cold Half + Hot Half) up to 200 cavities

- Existing mold conversions (full or partial conversions)

- Spare parts for molds and components

- Spare parts for Hot Halves and components

- Mold refurbishment

- Electric temperature control units

APPLICATIONS

Our range of solutions is wide and versatile. We can supply moulds with up to 200 cavities for standard applications like mineral water or soft drinks, however we have a wide range of solutions also for special applications like wide mouth preforms or long preforms for 5 gallon containers.

-

Discover more/02

- SIPA

Discover the other sections of Moulds

Discover our injection preform molds, blow molds, and tooling refurbishment and reconditioning solutions.

Refurbishment, conversion

30

/

06

/

2025

Refurbishment, conversion

Our flexible conversion and refurbishment services help you make the most of your tooling. For example, our LongLife service extends the life of preform mould cold halves up to 12 million cycles before first maintenance is needed.

Blowing moulds

30

/

06

/

2025

Blowing moulds

SIPA supplies blow moulds for the beverage, food, and consumer goods industry to fit most of the major brands of re-heat stretch blow moulder machines. Our blowing specialists can advise you on how to achieve the best possible bottle quality even before the start of the production.In our laboratories, extensive tests and inspections are performed on both molds and sample bottles through high-quality measuring and testing equipment. SIPA produces aluminum and stainless steel moulds for any...

Preform tooling

30

/

06

/

2025

Preform tooling

In second place in the world for the production of molds, SIPA is able to deliver global tooling programs for new molds or mold conversions from single to 200 cavities. To ensure top quality, every SIPA mold is tested before shipping on dedicated XFORM machines.

News for this products

Intelligence in the mold: SIPA unveils XBRAIN for advanced digital management

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements

13

/

01

/

2026

Celebrating our sustainability achievements

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

12

/

12

/

2025

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW Wins Top Sustainability Award

13

/

11

/

2025

SIPA's XFORM RENEW Wins Top Sustainability Award

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

Introducing XLABL RF: New Frontier in Roll-Fed Labelling Technology

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

27

/

01

/

2026

Intelligence in the mold: SIPA unveils XBRAIN for advanced digital management

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

13

/

01

/

2026

Celebrating our sustainability achievements

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

12

/

12

/

2025

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

13

/

11

/

2025

SIPA's XFORM RENEW Wins Top Sustainability Award

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

07

/

11

/

2025

Introducing XLABL RF: New Frontier in Roll-Fed Labelling Technology

Discover SIPA's XLABL_RF, the cutting-edge roll-fed labelling machine that offers precision, flexibility, and efficiency for PET containers.

Case Histories for this products

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

17

/

02

/

2026

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

14

/

01

/

2026

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

10

/

12

/

2025

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

01

/

10

/

2025

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.