Moulds

SIPA's experience and expertise in PET bottle production extends throughout the entire process to include injection and blowing moulds as well as machines. And it's all about helping the customer to make a better preform or bottle, more cost effectively.

-

Home/ Moulds

- SIPA

Injection tooling for PET preforms and blowing moulds: solutions for life

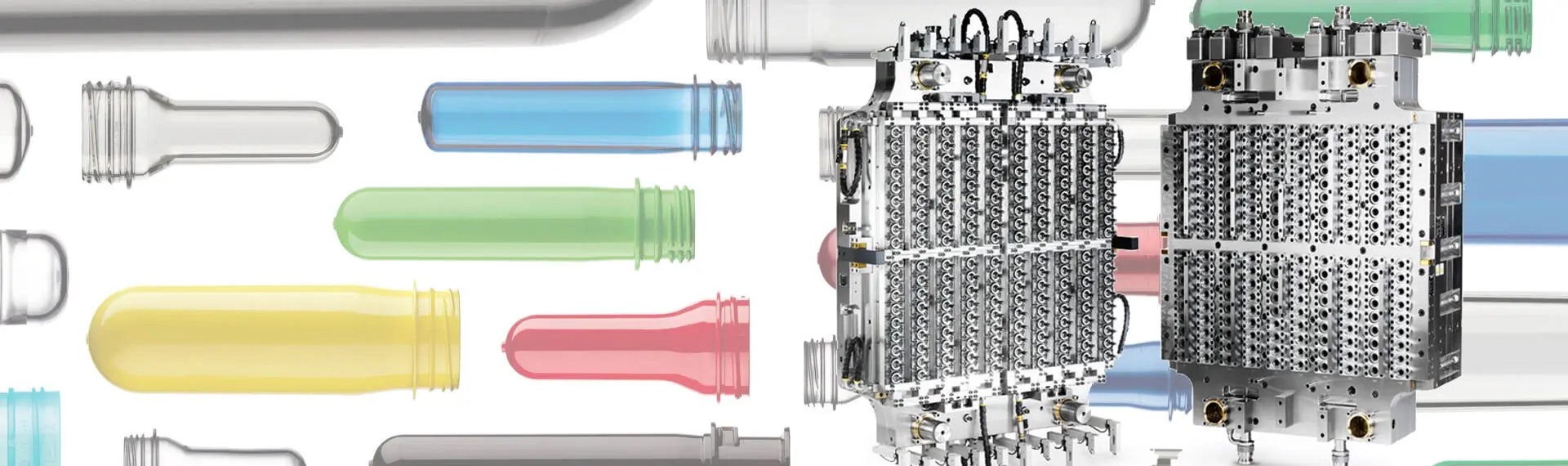

SIPA supplies complete preform moulds for any PET machine up to 200 cavities, including cold halves, hot halves, conversion kits, spare parts, and full refurbishment services. Every mould is tested on dedicated XFORM machines to ensure top quality, with solutions for all applications, from narrow necks to wide mouths and thick walls.

We also produce high-quality blow molds for PET containers, compatible with most major reheat stretch-blow molding machines. Available in aluminum or stainless steel, our molds suit any shape and include a variety of decorative options.

State of the Art Tooling Production

SIPA's tooling department boasts a huge, state-of-the-art production site for injection & blow molds, making it one of the largest in the world. We've heavily invested in new production islands, adopting a one-piece-flow production logic and a continuous improvement philosophy. This commitment, coupled with constant monitoring, focuses on delivering individual customer value and eliminating waste, which has significantly reduced lead times while elevating product quality.

-

Discover more/02

- SIPA

Discover the other sections of Moulds

Discover our injection preform molds, blow molds, and tooling refurbishment and reconditioning solutions.

Refurbishment, conversion

30

/

06

/

2025

Refurbishment, conversion

Our flexible conversion and refurbishment services help you make the most of your tooling. For example, our LongLife service extends the life of preform mould cold halves up to 12 million cycles before first maintenance is needed.

Blowing moulds

30

/

06

/

2025

Blowing moulds

SIPA supplies blow moulds for the beverage, food, and consumer goods industry to fit most of the major brands of re-heat stretch blow moulder machines. Our blowing specialists can advise you on how to achieve the best possible bottle quality even before the start of the production.In our laboratories, extensive tests and inspections are performed on both molds and sample bottles through high-quality measuring and testing equipment. SIPA produces aluminum and stainless steel moulds for any...

Preform tooling

30

/

06

/

2025

Preform tooling

In second place in the world for the production of molds, SIPA is able to deliver global tooling programs for new molds or mold conversions from single to 200 cavities. To ensure top quality, every SIPA mold is tested before shipping on dedicated XFORM machines.

Work with us

We are always looking for dynamic and proactive people, oriented towards growth and achieving results. On this page you can find the list of our open positions. Click on an offer to learn more about the position and, if you match the required profile, fill out the form. If there are currently no positions of interest or in line with your profile, send us your CV using the Spontaneous Applications section.

Contact Us

Please let us know how we can assist you. We have dedicated contact forms for specific inquiries, ensuring your request reaches the right department for a swift and accurate response.

By your side, beyond the limits.

Every shape, every technology, every need about PET packaging.

By your side, beyond the limits.

Every shape, every technology, every need about PET packaging.

Drinktec | 2025