- Home / Robotic handling systems

- SIPA

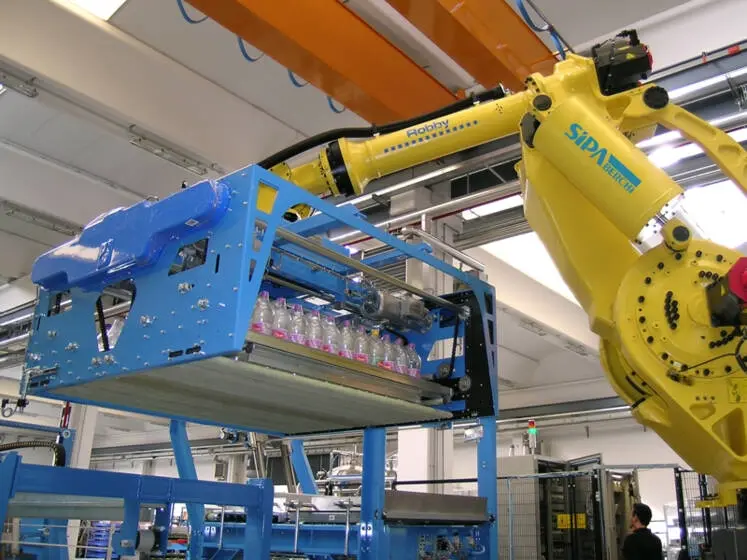

ROBBY : Robotic palletizing and manipulation systems

The Robby system is a comprehensive approach developed by Sipa to meet the increasing market demand for packaging flexibility and efficiency for a wide range of containers, packaging and secondary packaging. In particular, it offers an extremely viable alternative to traditional palletizing and depalletizing systems.

By integrating an anthropomorphous robotic arm with the other components required, Sipa can create equipment and systems for palletizing, depalletizing and handling packages, crates, cartons, packs, bottles, cans, pallets and interlayer pads.

HIGHLIGHTS

/

01

- Flexibility: it can handle any type of container and serve multiple lines at the same time.

- Footprint: it easily adapts to extremely reduced footprint areas.

- Modularity and integrability: custom-made configurations can be created to meet a wide range of needs.

- Convertibility: it can be easily relocated or converted if needed.

- Reliability: Movements are extremely precise and consistent.

- Speed and Efficiency: can be applied to a wide range of production speeds, including high end.

- Maintenance: Reduced maintenance costs thanks to high product industrialization.

- Size change: change-over time is very short, both for product and head change.

GENERAL FEATURES

/

02

In addition to its experience in creating the right system configuration and managing installation electronics, Sipa’s breakthrough lies in the design and realization of a gripper head for each product type and all movement modes.

Its long-time experience in robotized manipulation has allowed Sipa to create a wide range of heads:

- halving platform

- pliers-type

- jaw-head and hook

- permanent magnet with release

- vacuum head

- inflatable pipes

- cap-type for lipped and lipless bottles

- suction cup

These are multifunction heads designed to handle not only the product but also other related elements such as empty pallets, plastic or cardboard interlayer pads, display trays, etc.

Its broad range of traditional palletizing equipment allowed Sipa to realize the full potential of solutions for product feed and layer preparation in order to meet any positioning need in any operational setting. Fully automatic gripping head change-over is available on option, and new palletizing patterns can be simply programmed directly in the operator control panel.

Thanks to their flexibility robotic solutions perfectly adapt to special operations such us display palletising, bottle transferring, on pallet configuration modification, empty pallet control device, etc.

ROBBY PAL: LAYER PALLETIZER

/

03

An extremely complete solution to handle different types of containers and products. Thanks to its versatility and reliability, it is one of the most widely-used on medium- and high-speed bottling lines.

This configuration can use the following head types:

- halving platform for packs and cartons

- jaws and hooks for plastic crates with and without windows

- magnet with release for tin containers or those with metal lids

- vacuum head for uniform, stable packs (e.g., packs of cans)

When required (for speed reasons, type of product, etc.) the Fastlayer robotic layer preparation with active pack orientation can be included.

Robby Pal layer handling applications are extremely flexible and can be designed to palletize a range of pallet sizes as well as half- and quarter-pallets.

Products that can be processed

- Packs

- Cartons

- Crates

- Cans

- Tin containers

ROBBY PAL: ROW PALLETIZER

/

04

This type of pick-up is suitable for low- and medium-speed lines, but also to handle special shape or large containers.

The size and shape of the grippers have been designed on the basis of the type of container or package to be handled.

On this type of equipment, accessory devices can be integrated into the product gripper head (for example, interlayer or empty pallet grippers) which greatly reduces the amount of required space.

In traditional palletizing systems, this equipment is normally separate and occupies a significant amount of space.

Products that can be processed

- Packs

- Cartons

- Crates

- Big size bottles

ROBBY PAL: MULTIHEAD AND LOOSE PRODUCT PALLETIZER

/

05

This configuration is used to palletize both filled and empty loose containers in glass or PET:

- cap-type for lipped and lipless bottles

- row pliers-type

- inflatable pipe

- vacuum head

If required by the application, self-adjusting heads can also be provided to handle special products or products in various sizes.

For this type of application, the row infeed and preparation area is extremely important because often the equipment handles products that are especially unstable or delicate.

Palletization may be carried out directly on the pallet, or cardboard or plastic display tray.

These applications can be integrated into MULTIHEAD solution—a single palletization island that can handle a variety of products utilizing two different layer prep zones and two different head types, one for packs and the other for loose bottles. The robotic arm is positioned in the center and, thanks to a rapid head change system, can comfortably work with the current layer prep to palletize the type of selected product.

Products that can be processed

- Loose PET bottles (filled or empty)

- Loose glass bottles (filled or empty)

- Jars

ROBBY RACK: LARGE-SIZE PALLETIZER ON RACKS OR PALLETS

/

06

This application is particularly suitable for handling 3- and 5-gallon bottles.

Sipa first presented this configuration in 2000 and since then has acquired significant experience in handling a range of 5 gallon bottle types, including round, triangular and rectangular.

Numerous types of racks have also been utilized in both metal and plastic, and palletization on pallets completes the configuration options for this type of application.

Its 6-axis robotic configuration is especially good for complex movements, making it extremely suitable for handling “special” containers and packages, including large-sized ones such as canisters, drums, kegs, etc.

Again here the heart of the application is its head designed for optimum gripping during the entire handling process, without damaging the container in any way.

Depending on the installation speed, multiple heads can also be mounted in order to handle a number of containers simultaneously (from 1 to 10 during racking of full 5 gallon bottles) with the choice of robot model based on the weight to be handled.

A modular gripping system has been designed to provide for interchangeability of the grippers as the installation evolves over time.

For these operations, movement precision, reliability and consistency are fundamental, but there are also safety measures against unforeseen problems, such as damaged or defective racks. In these situations, the internal safety program stops the machine before the installation is damaged.

Robby Rack may be used for either depalletizing or palletizing lines, as well as in combined cycles to simultaneously empty and fill the rack.

If required by the application, self-adjusting grippers to handle special racks or ones of different size can also be supplied.

APPLICATIONS

Solution for handling of packs, Cartons, Crates, shrink-packs, bottles, jars, pallets and interlayer, full or empty loose containers.

-

Discover more/02

- SIPA

Discover the other sections of Secondary Packaging

Explore our comprehensive range of secondary packaging services: from initial design and engineering to prototyping containers that bring your unique packaging vision to life.

Robotic handling systems

06

/

07

/

2025

Robotic handling systems

Learn about our robotic handling systems, offering versatile solutions for complex packaging tasks with high reliability and flexibility.

Depalletisers

06

/

07

/

2025

Depalletisers

Explore our range of depalletisers, engineered to streamline the unloading process with high efficiency and minimal manual input. See the benefits

Palletisers

06

/

07

/

2025

Palletisers

Discover our innovative palletisers, designed to automate the palletizing process with precision and high throughput. Learn how they enhance your production.

News for this products

SIPA Additive: reimagined 3D printing fast prototyping

25

/

02

/

2026

SIPA Additive: reimagined 3D printing fast prototyping

SIPA has officially launched SIPA Additive, a new service designed to provide customers with a fast and cost-effective solution for packaging development. Located at the SIPA HQ Plant, the dedicated...

Intelligence in the mold: SIPA unveils XBRAIN for advanced digital management

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

Celebrating our sustainability achievements

13

/

01

/

2026

Celebrating our sustainability achievements

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

12

/

12

/

2025

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

SIPA's XFORM RENEW Wins Top Sustainability Award

13

/

11

/

2025

SIPA's XFORM RENEW Wins Top Sustainability Award

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

25

/

02

/

2026

SIPA Additive: reimagined 3D printing fast prototyping

SIPA has officially launched SIPA Additive, a new service designed to provide customers with a fast and cost-effective solution for packaging development. Located at the SIPA HQ Plant, the dedicated...

27

/

01

/

2026

Intelligence in the mold: SIPA unveils XBRAIN for advanced digital management

While high-performance machinery is the backbone of PET production, the future of manufacturing lies in the data hidden within the mold. SIPA is proud to introduce XBrain, an advanced telemetric and...

13

/

01

/

2026

Celebrating our sustainability achievements

Celebrating our sustainability achievements: SIPA earns Gold Medal from Ecovadis With an overall score of 78/100 SIPA has been awarded a Gold medal from EcoVadis Sustainability Rating placing us...

12

/

12

/

2025

XFORM Progress: From GEN 4 to PRO - setting new standards in high-cavitation PET preform production

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

13

/

11

/

2025

SIPA's XFORM RENEW Wins Top Sustainability Award

SIPA's XFORM RENEW wins Sustainability Awards 2025 for its efficient PET recycling tech, reducing CO₂ emissions and energy use while lowering costs.

Case Histories for this products

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

Driving Innovation and Efficiency in PET Packaging

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.

17

/

02

/

2026

SIPA and Wahaha Group: a strong partnership for PET Preform Manufacturing in China

SIPA is proud to highlight its significant collaboration with Wahaha Group, a leading force in China's dynamic beverage industry. This strategic partnership underscores SIPA's commitment to...

14

/

01

/

2026

SIPA and Arma Food: a collaborative approach to edible oil packaging in Egypt

The long-standing cooperation between SIPA and Arma Food is built on a shared commitment to quality and market-driven innovation.

10

/

12

/

2025

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

Corporación AZENDE of Ecuador Boosts Production with SIPA Sincro Bloc Technology

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

07

/

11

/

2025

Driving Innovation and Efficiency in PET Packaging

ALSAD's GM Talal Yamani shows how SIPA's advanced PET technology drives innovation, efficiency, and sustainability in Saudi Arabia's packaging industry.

01

/

10

/

2025

SIPA and Sarl Noua: A Winning Partnership for the Algerian Beverage Market

Sarl Noua partners with SIPA to launch premium, sustainable mineral water, featuring innovative bottle design and high-speed production capabilities.