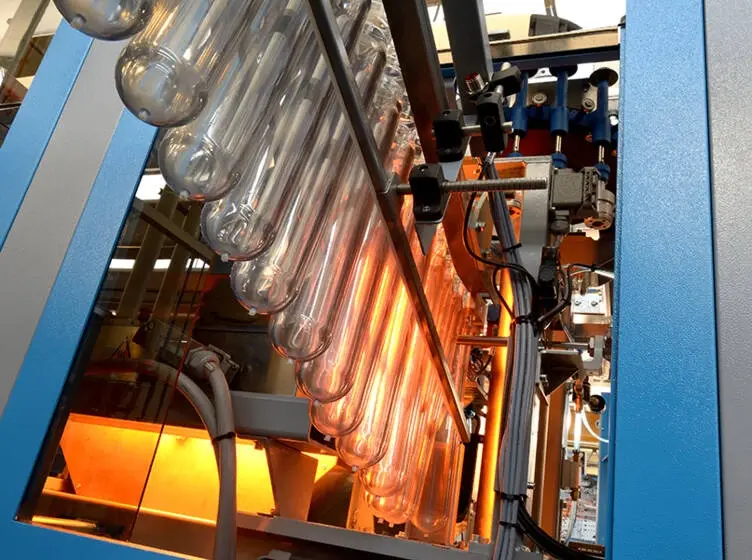

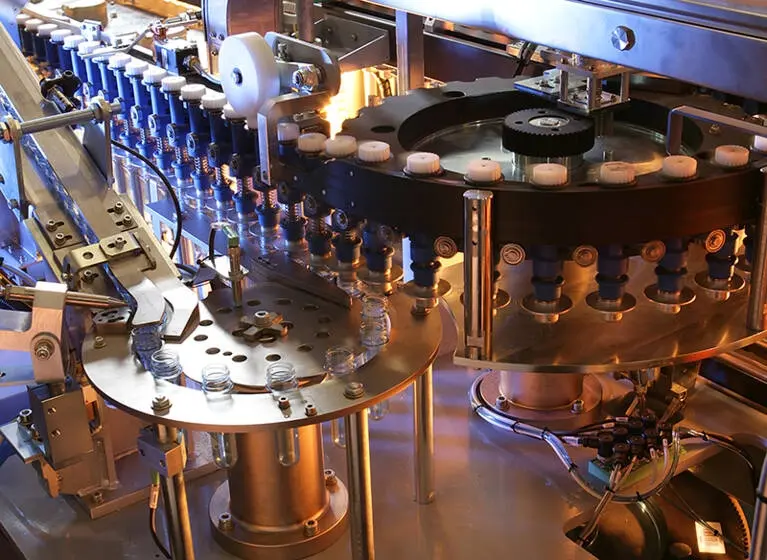

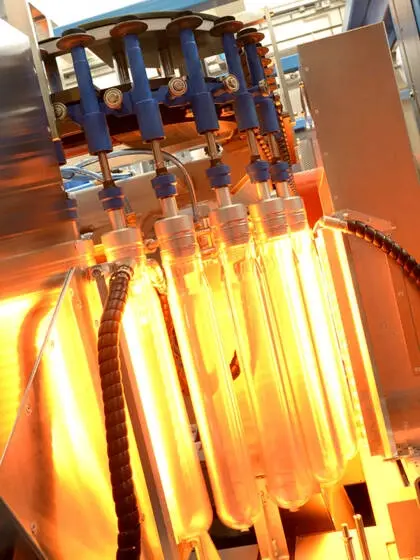

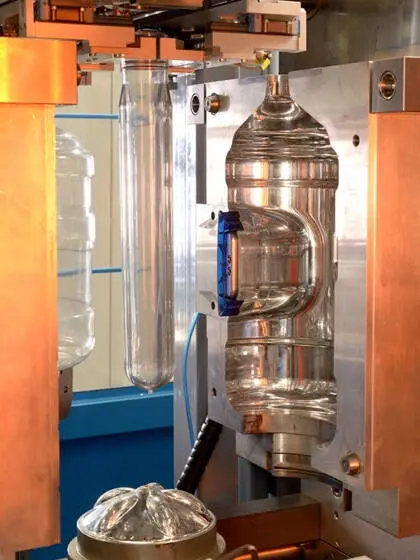

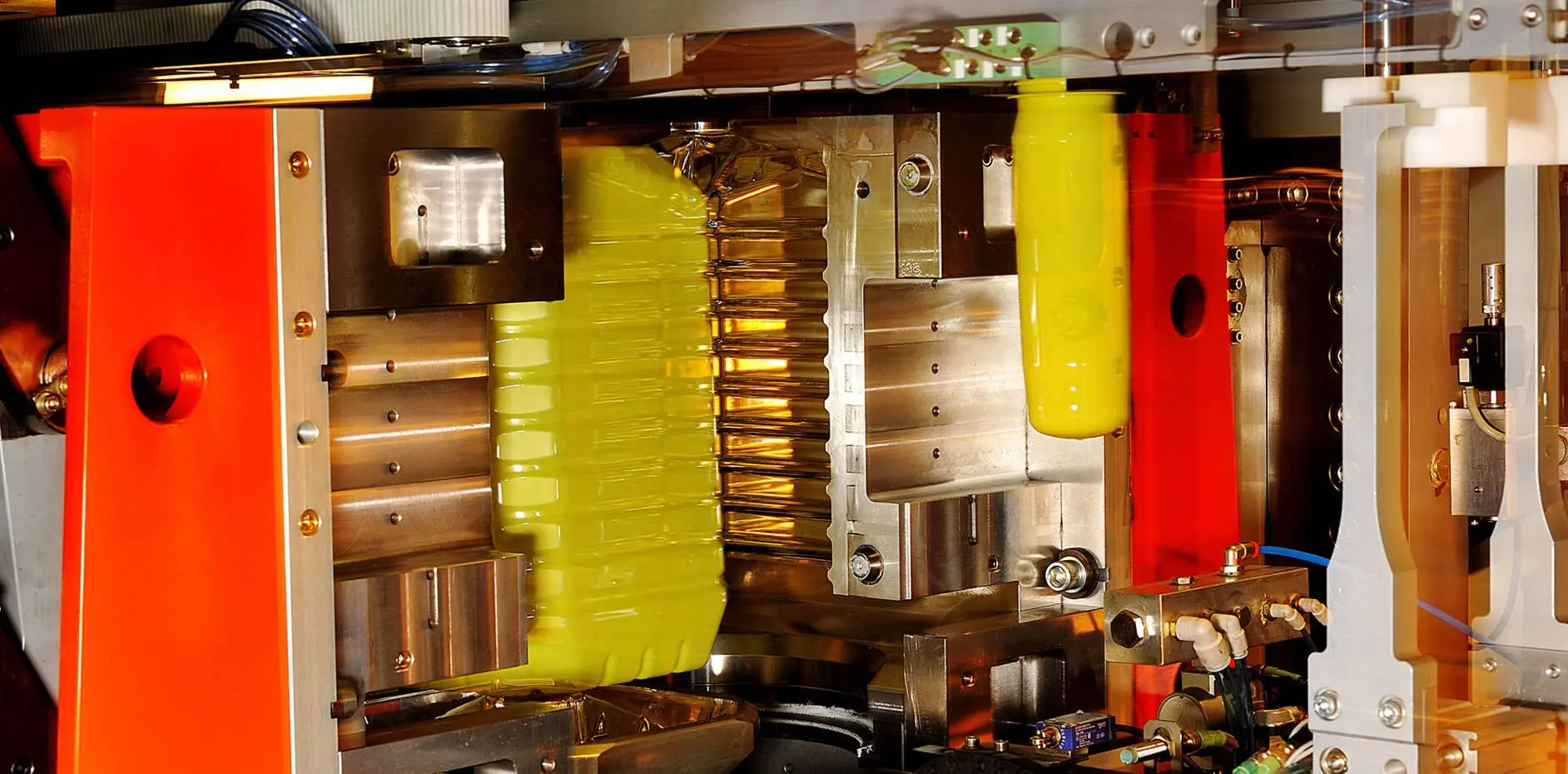

The SFL BIG and SFL MAXI linear blowers are the response for small- and medium-scale production systems of containers anywhere from 12 to 30 liters in size, dedicated to sectors like mineral water, edible and mineral oil, beer, wine and household chemicals lines.

Both platforms are ideal for the production of returnable or one-way containers for water dispensers, stackable/one-way containers, kegs for beer and a wide range of large size containers, with neck wide finishes. A special feature is the automatic insertion of the handle inside the blowing mold.

Contact Us

Contact Us