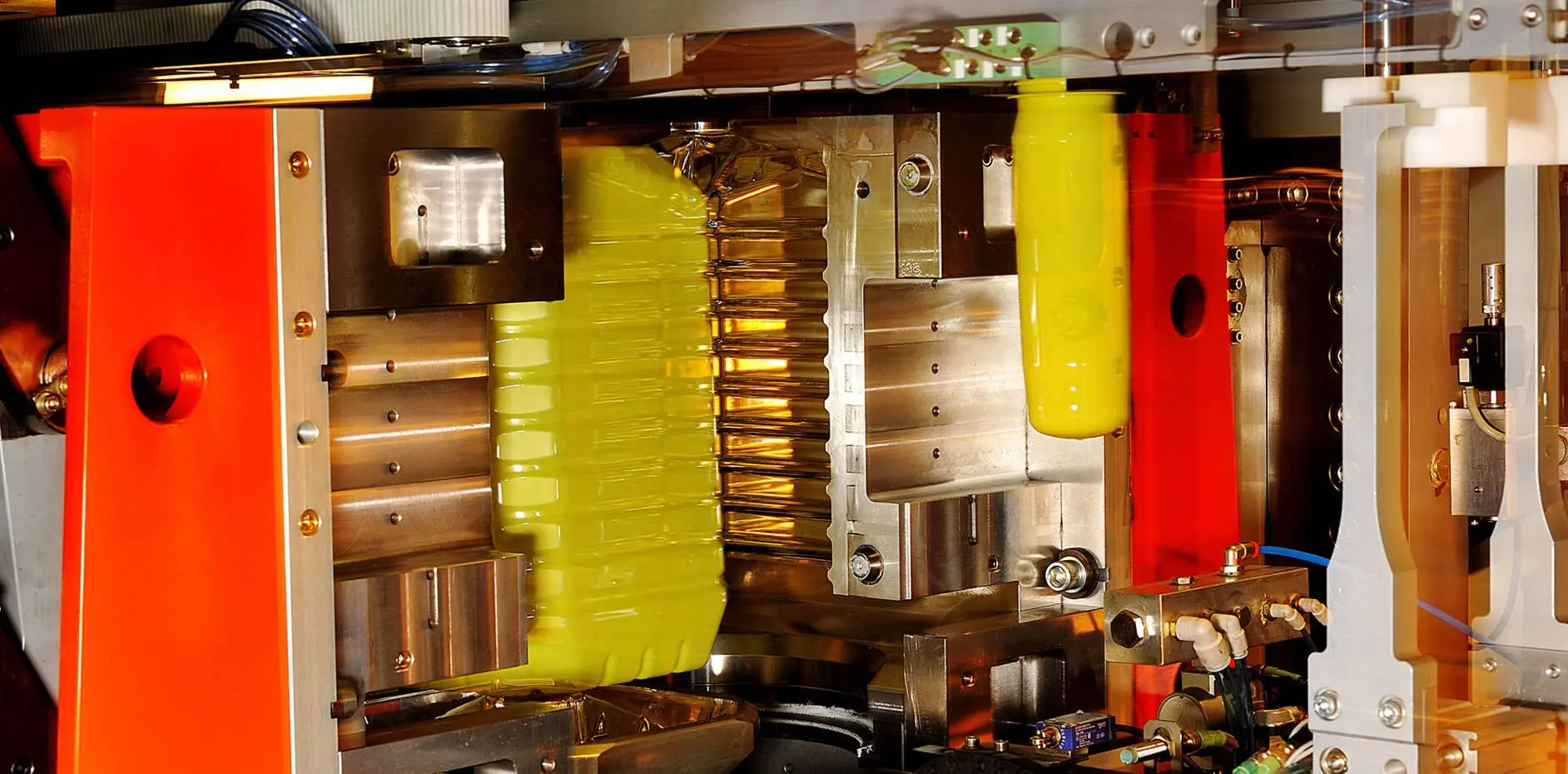

ECS SP platforms are ideal for manufacturing containers with diverse designs and characteristics, catering to a wide range of industries including cosmetics, personal care, detergents, food, pharmaceuticals, and miniature beverages, typically 20, 30, and 50 mL, commonly used for non-food items such as pharmaceuticals and hotel amenities.

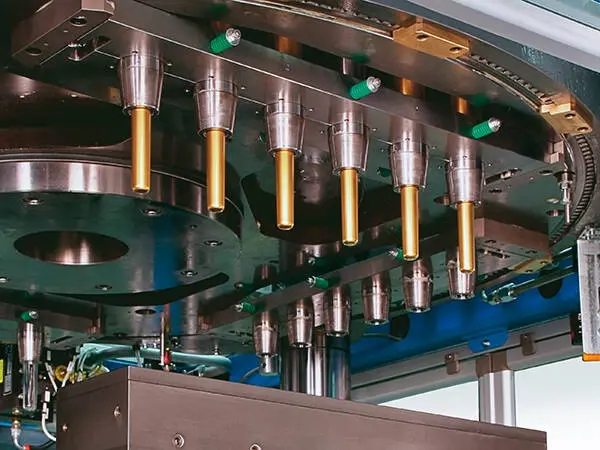

The ECS SP models (SP 25 and SP 80 with single row, SP 130 with double row) integrate hydraulics for high-force applications (e.g., clamping tonnage) with servo-electric drives for rapid movements (e.g., blowing unit operation). This hybrid approach ensures high energy efficiency. They also offer compatibility with molds originally designed for major competitors' equipment.

Contact Us

Contact Us